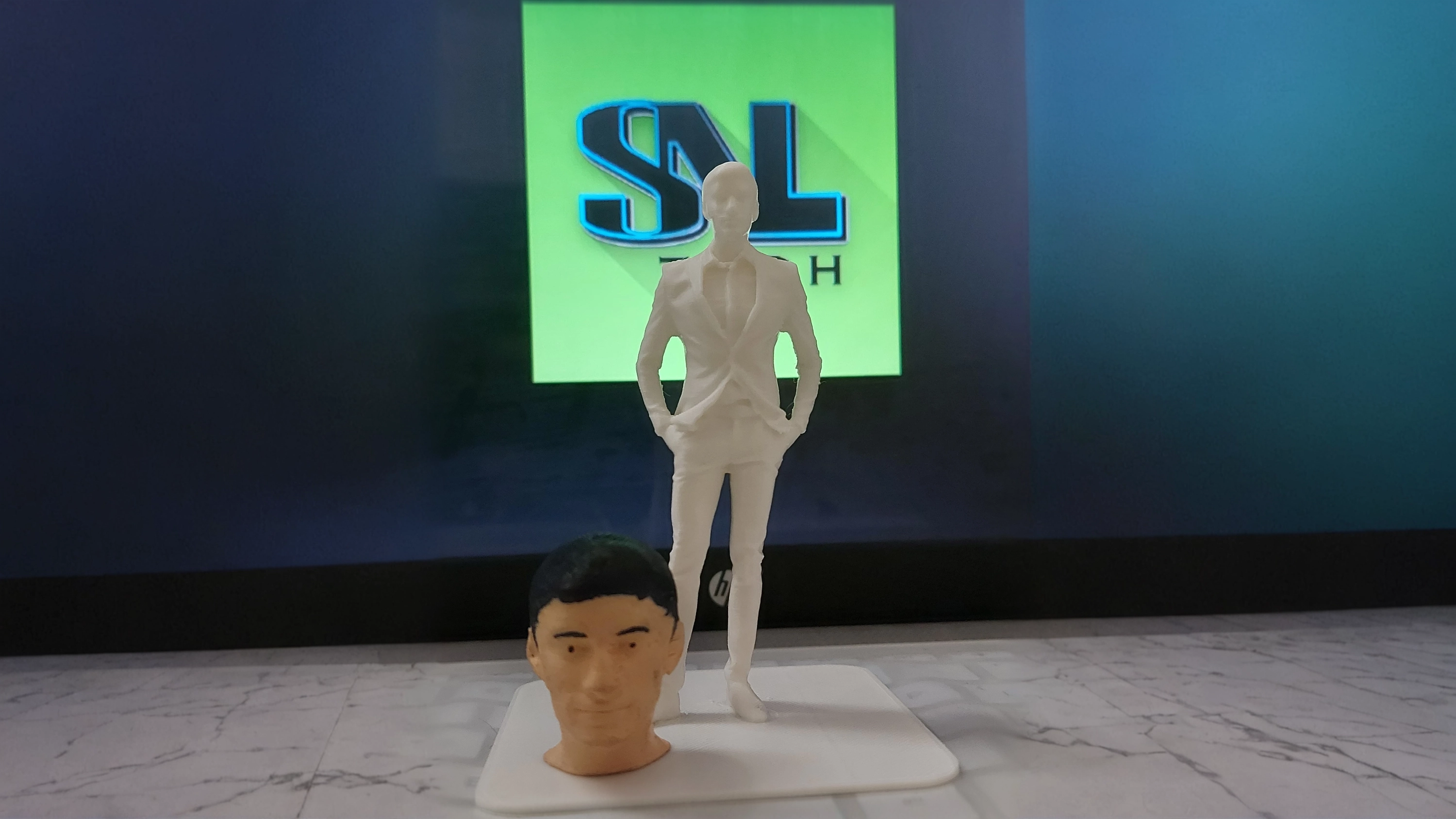

This was a creative yet technically demanding project that blended artistic modeling, 3D printing calibration, and physical post-processing. The goal was to produce a miniature figurine of myself using digital modeling and desktop fabrication tools. I began by sculpting a likeness in Blender, referencing multiple angled photos to approximate facial structure, pose, and proportions. The model was split into printable components, with orientation and support strategy optimized in the slicer to minimize overhang artifacts.

I used a Creality Ender3 printer for fabrication, experimenting with PLA, PETG, and silk PLA to assess finish quality. Layer height, infill pattern, and wall thickness were adjusted across prototypes until I achieved a balance between print speed and surface detail. Post-print processing involved meticulous sanding of support scars and layer seams, followed by multiple coats of resin and acrylic paint to give the figurine a polished, life-like appearance.

To extend the project further, I replicated the process for a few friends — customizing their poses, accessories, and clothing folds based on personality traits. I also developed a 3D-printable modular stand system using parametric design in Fusion360, enabling interchangeable baseplates and name tags.

The project required both technical precision and artistic sensitivity — and it deepened my respect for iterative prototyping and real-world tolerancing. It also proved to be an excellent exercise in understanding the limitations of affordable additive manufacturing, especially when the goal is both mechanical stability and aesthetic refinement.